When it comes to manufacturing complex metal parts, the choice of casting method is crucial. Two prominent techniques often considered are investment casting and sand casting. Each method has its distinct advantages and applications, making them suitable for different scenarios. In this comprehensive guide, we’ll delve into the nuances of investment casting versus sand casting, helping you make an informed decision for your next project.

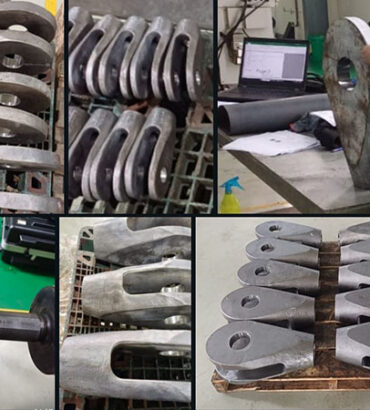

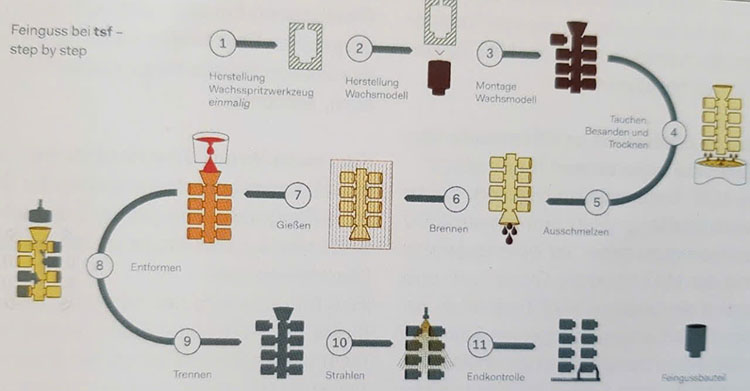

What is investment casting?

Investment casting, also known as lost-wax casting, is a precise and versatile process that involves creating detailed and high-quality metal parts. The process begins with creating a wax model of the desired part, which is then coated with a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a cavity in the shape of the part. Molten metal is poured into this cavity, solidifying to form the final product. After cooling, the ceramic shell is removed, revealing the intricate metal part.

Advantages of investment casting

High precision and surface finish: Lost-wax casting is renowned for its ability to produce parts with exceptional dimensional accuracy and fine surface finishes. This makes it ideal for components with intricate details and complex geometries.

Material versatility: This method can be used with a wide range of metals, including high-temperature alloys, stainless steel, and superalloys. This versatility is crucial for applications in aerospace, automotive, and medical industries.

Reduced machining costs: The high precision of investment casting often means that parts require less post-casting machining, which can reduce overall manufacturing costs.

Applications of investment casting

Investment casting is often employed in industries where precision and complexity are paramount. Common applications include:

- Aerospace components: Engine parts, turbine blades, and structural components.

- Medical devices: Surgical instruments and implants.

- Automotive parts: Engine components and high-performance parts.

- Vehicle construction: Engine components parts.

- Machine construction: Details and components in industrial machinery.

What is sand casting?

Sand casting, a more traditional and widely used method, involves creating a mold from a mixture of sand and binders. The process starts with creating a pattern of the part to be cast, which is then used to form a mold cavity in the sand. Molten metal is poured into this cavity, and once it solidifies, the sand mold is broken away to reveal the cast part.

Advantages of sand casting

Cost-effective for low to medium production runs: Sand casting is relatively inexpensive compared to investment casting, particularly for low to medium volume production. The molds are typically made from sand, which is affordable and easy to work with.

Flexibility in part size and weight: Sand casting can accommodate a wide range of part sizes, from small components to large, heavy parts. This flexibility makes it suitable for various industries, including construction and machinery.

Simplified mold creation: The sand mold can be quickly created and modified, allowing for faster prototyping and adjustments compared to more intricate methods like investment casting.

Applications of sand casting

Sand casting is versatile and used in many industries for a broad range of applications:

- Automotive Industry: Engine blocks, transmission cases, and other heavy components.

- Construction Machinery: Parts for excavators, cranes, and other equipment.

- Machine Industry: Large components such as propellers and engine parts.

Investment casting and sand casting: Key different

| Differences | Investment casting | Sand casting |

| Casting time | Investment casting cycle takes longer | Sand casting cycle is shorter |

| Quality appearance | Investment casting products have smoother surfaces | The final product of sand casting is often rough, depending on the type of sand used. |

| Materials | Unlimited | Unlimited |

| Design | It is necessary to shape the product to create the desired shape. | Less time required to create sand casting molds |

| Range of products | Aerospace components parts, medical devices parts, automotive parts,… | Automotive parts, construction machinery, Machine industry, |

| Mass production | Suitable for mass production | More difficult to mass produce |

| Cost | More expensive | Cheaper |

To choose an effective casting method, customers need to evaluate each factor of the benefits of each casting process, material, cost, application to help determine the most effective method. At GTR Casting Vietnam, we provide precise, high-tech casting methods to suit your casting needs. Please contact GTR Casting Vietnam for the most professional advice.

See more:

- Aerospace Casting Parts Overview: Advantages, applications

- What is investment casting? – GTR Vietnam

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919