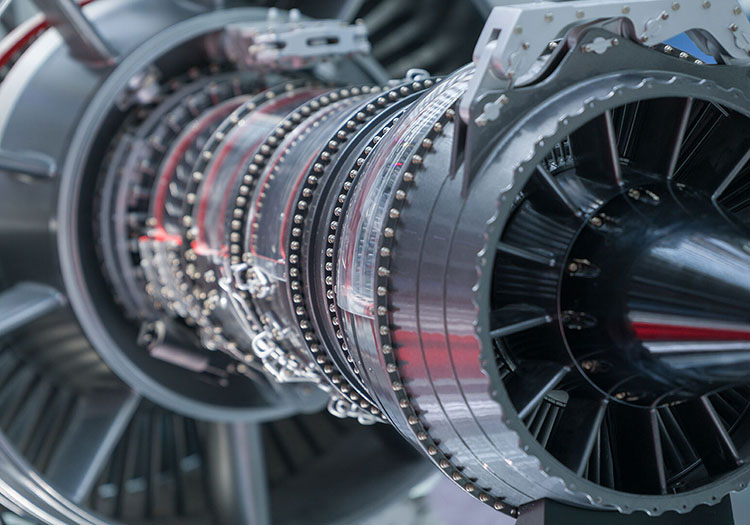

In the aerospace industry, components and machine parts require a high level of safety, accuracy, efficiency, and innovation. As a result, the development of investment casting has propelled the growth of aerospace casting. This method not only meets the stringent demands of the aerospace sector but also saves costs and reduces waste. Let’s explore the advantages of aerospace investment casting in the following article.

Advantages of aerospace investment casting

Exquisite design and high precision

The advantage of aerospace investment casting is its ability to produce components with tight tolerances. Precision is a critical factor in the aerospace industry, as even the smallest deviation can have a significant impact on safety and performance. This casting method allows for the creation of complex designs, eliminates unnecessary excess material, and optimizes shapes with a focus on the outstanding functionality of aerospace components.

Material versatility

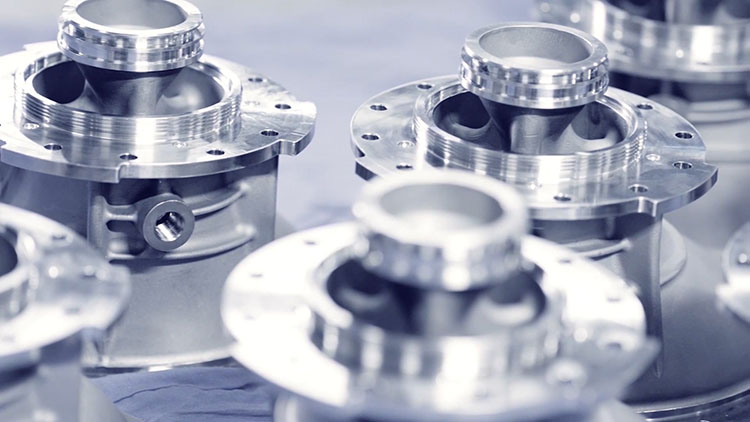

The investment casting method of GTR Vietnam Cast Company supports a variety of materials such as stainless steel, titanium, and high-performance alloys. These materials offer high strength, lightweight properties, and are suitable for manufacturing machine parts in the aerospace industry. The ability to cast parts from specialized alloys further enhances performance in demanding aerospace applications.

Reduced waste and cost-effectiveness

Compared to traditional casting methods, the investment casting process minimizes excess materials. By producing parts with high geometric accuracy, engineers can significantly reduce the amount of excess material that is typically machined away. As a result, investment casting not only lowers production costs but also saves manufacturing time.

Improved surface finish

Aerospace investment cast components require superior surface finish to enhance durability and performance. The smooth surfaces achieved through the investment casting process can also improve the aerodynamic properties of the parts, contributing to overall efficiency.

Consistent quality

The investment casting process is highly repeatable, allowing for consistent quality across large production runs. Aerospace manufacturers rely on this consistency to ensure that each part meets rigorous industry standards and regulatory requirements. Advanced quality control measures during the casting process further guarantee that every component is produced to the highest level of quality.

Thin-walled sections

Investment casting can produce components with thin, lightweight walls, reducing weight while ensuring the necessary strength and performance characteristics. This is a crucial factor in aerospace applications, where lightweight structures are essential for improving overall performance and fuel efficiency.

GTR Vietnam – Top quality aerospace investment casting company

GTR Vietnam stands out as a premier aerospace investment casting company, renowned for its commitment to quality and innovation. With state-of-the-art technology and a team of skilled engineers, GTR Vietnam specializes in producing high-precision components that meet the stringent demands of the aerospace industry. Our investment casting process not only minimizes material waste but also ensures exceptional surface finishes, enhancing both durability and performance. By focusing on lightweight designs without compromising strength, we empower our clients to achieve superior efficiency and reliability in their aerospace applications. Trust GTR Vietnam for your investment casting needs, where excellence is our standard.

See more:

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919