Precision investment casting is a significant turning point in industries that require high precision and complex metals. This technique is widely applied in various fields such as aerospace, medical, and automotive industries. By combining modern technology with precise investment casting methods, it has produced products with intricate shapes and excellent surface finishes. Let’s explore precision investment casting with GTR Vietnam Cast Company.

What is precision investment casting?

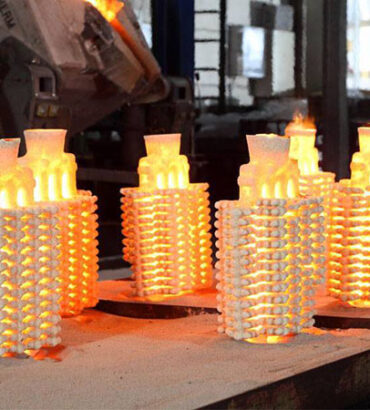

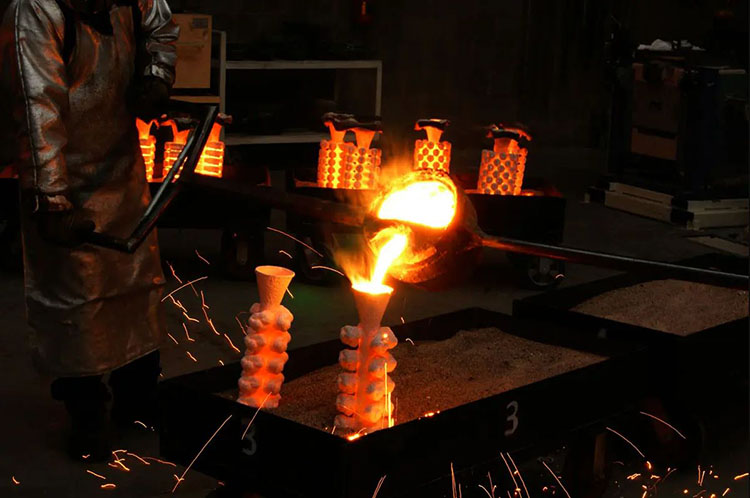

Precision investment casting is a modern casting technique used to create high-precision and complex metal parts. This method involves producing a wax model that accurately reflects the desired shape of the product. The wax model is then coated with a layer of ceramic material to form a mold. Once the wax is melted and removed, molten metal is poured into the mold to create the part’s shape. After cooling, the ceramic mold is broken away, and the product is finished. Precision investment casting helps reduce machining costs, improve material properties, and enable the creation of complex geometries that are difficult to achieve with traditional casting methods. This process is ideal for producing intricate shapes with a smooth surface finish. Products made using this technique are widely applied in aerospace, medical devices, and automotive industries.

Advantages of precision investment casting

High accuracy

The outstanding advantage of the precision investment casting method is its tight tolerances and ability to achieve high accuracy. The casting process allows for the creation of highly complex geometries that require almost absolute precision. This precision is critical in industries such as aerospace, where even minor deviations can lead to significant issues.

Excellent surface finish

The ceramic shell used in investment casting results in a smooth surface finish on the final product. This reduces the need for extensive post-processing and allows for components to be used directly in applications, saving both time and costs.

Material versatility

Precision investment casting can be performed with a wide range of metals and alloys, including stainless steel, carbon steel, and nickel-based superalloys. This versatility makes it suitable for various applications across different industries.

Reduced material waste

Compared to traditional machining methods, precision investment casting generates less material waste. The process allows for the recycling of excess metal, contributing to more sustainable manufacturing practices.

Applications of precision investment casting

Aerospace industry

In the aerospace sector, precision investment casting is used to create critical components such as turbine blades, housings, and brackets. The high strength-to-weight ratio and precise tolerances make it an ideal choice for parts that must withstand extreme conditions.

Medical devices

Precision investment casting is increasingly utilized in the medical field for manufacturing surgical instruments, implants, and other specialized devices. The ability to produce complex shapes with high accuracy ensures that these components meet stringent regulatory standards.

Automotive sector

The automotive industry benefits from precision investment casting for producing lightweight components that improve fuel efficiency and performance. Parts such as engine blocks, transmission housings, and custom fittings are often made using this method.

Precision investment casting is a vital manufacturing technique that offers numerous advantages, including high accuracy, excellent surface finish, and material versatility. Its applications span various industries, making it an essential method for producing complex metal parts. As technology continues to evolve, precision investment casting will remain a key player in advancing manufacturing capabilities and meeting the demands of modern industry.

Why choose the precision investment casting in GTR Vietnam Cast Company?

Choosing precision investment casting at GTR Vietnam Cast Company offers numerous benefits that set us apart in the industry. Our advanced technology and skilled workforce ensure that we produce high-quality components with exceptional accuracy and intricate designs. We prioritize quality control at every stage of the casting process, guaranteeing tight tolerances and superior surface finishes. Additionally, our commitment to using premium materials enhances the durability and performance of the final products.

With extensive experience across various sectors, including aerospace, automotive, and medical, we understand the unique needs of our clients and strive to provide tailored solutions. Partnering with GTR Vietnam Cast Company means investing in precision, reliability, and innovation for your manufacturing needs.

See more:

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919