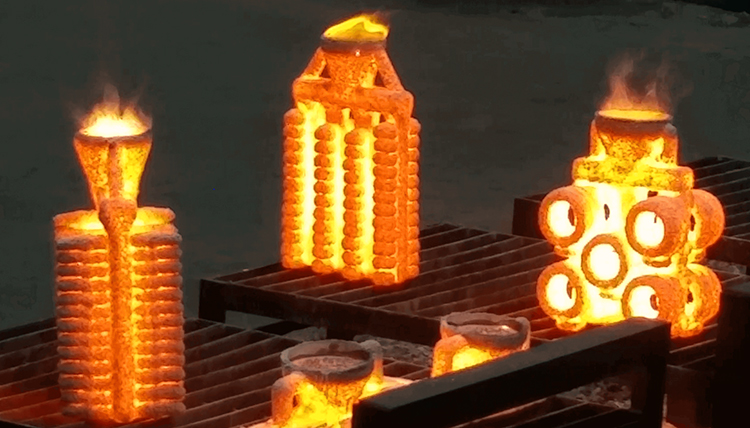

Investment casting, also known as lost-wax casting, is a casting method that delivers high precision and produces products with excellent surface finish. The advantage of this casting technique is that the resulting castings have complex shapes, high accuracy, and better quality compared to traditional casting methods. This method is applied in various industries. This article will share when it is appropriate to use investment casting.

Cases where investment casting method should be applied

Investment casting is widely used in many industries such as automotive, aerospace, precision industry, etc. The content below will share about when to use investment casting method.

Complex geometries

Components with complex geometries that require high precision are often produced using investment casting. Some parts and machine components in the aerospace and automotive industries, such as turbine blades and valve bodies, are commonly manufactured using this method. The ability to create detailed features reduces the need for secondary machining operations, ultimately saving time and cost.

Large production orders

Investment casting method, with its repeatable and consistent nature, allows for the production of large quantity orders. The initial cost associated with creating a pattern for investment casting is higher, but when producing in large quantities, it helps businesses save costs. This is a suitable casting method for businesses that require casting and producing the same part or component multiple times.

Save production costs

Investment casting is a suitable method for businesses seeking to optimize costs, minimize hazardous waste, and eliminate the need for post-production machining. This is a rapid mass production method that saves production time without compromising accuracy and quality.

High-temperature applications

Materials that must withstand extreme temperatures benefit greatly from investment casting. Superalloys and refractory metals can be cast into shapes that maintain integrity under harsh conditions. This makes investment casting the go-to choice for applications in aerospace engines and gas turbines, where durability is paramount.

Precise tolerances

Investment casting is renowned for its ability to achieve tight tolerances, often within ±0.005 inches. This precision reduces the likelihood of defects and minimizes the need for extensive post-processing. This quality is particularly valuable in industries where component reliability is critical, such as in medical devices or aerospace applications.

Diverse material applications

A notable advantage of this casting method is its ability to utilize a wide range of materials. From copper, aluminum, and iron to stainless steel and special alloys, lost foam casting accommodates many different material properties. This flexibility allows engineers to select the best material for their specific application, enhancing performance and durability.

Surface finish quality

Investment casting provides an exceptional surface finish, often requiring minimal machining. The smooth surfaces achieved through this method not only enhance aesthetic appeal but also improve functionality in applications where friction is a concern, such as in gears and bearings.

Why choose GTR Vietnam Cast Company?

Choosing GTR Vietnam Cast Company means partnering with a leader in precision casting and innovative manufacturing solutions. Our commitment to quality ensures that every product meets the highest industry standards. With advanced technology and a skilled team, we specialize in a wide range of materials, providing customized solutions to fit your needs. Our focus on sustainability and cost-efficiency helps businesses reduce waste and optimize production processes. Trust GTR Vietnam Cast Company for reliable service, exceptional craftsmanship, and a dedication to exceeding customer expectations.

See more:

- Investment casting vs sand casting: Choosing the right process for your needs

- GTR Vietnam Cast Company – Prestigious precision casting company

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919