With years of expertise in the industry, GTR has established itself as a trusted provider of high-quality and reliable casting solutions for construction vehicle manufacturers. At GTR Vietnam, we offer a comprehensive range of casting services tailored specifically to meet the needs of construction vehicle manufacturers. Our services include the production of a wide variety of parts and components essential for construction vehicles, such as wheels, chassis frames, exhaust systems, engine components, and much more. Our casting process utilizes premium-quality materials and undergoes stringent manufacturing procedures to ensure durability, precision, and optimal performance in the demanding applications of the construction vehicle industry.

What vehicle construction parts can die casting produce?

Beyond engine blocks and transmission cases, die casting can be used to produced different parts such as:

- Engine parts: This includes complex parts like cylinder heads, engine blocks, and even some gas engine parts.

- Electronic vocer: Die casting is suitable for producing covers for gearboxes, shaded pole motors, stepper motors, and other electronic components within a vehicle.

- Single-piece structural elements: Shock towers and torque bars are examples of structural parts that can be efficiently produced using die casting.

- Other components: Die casting can also be used for parts like seat belt pulleys, retractor spools (for seat belts), stators (electric motors), and heat sinks.

Along with many other parts according to customer requirements

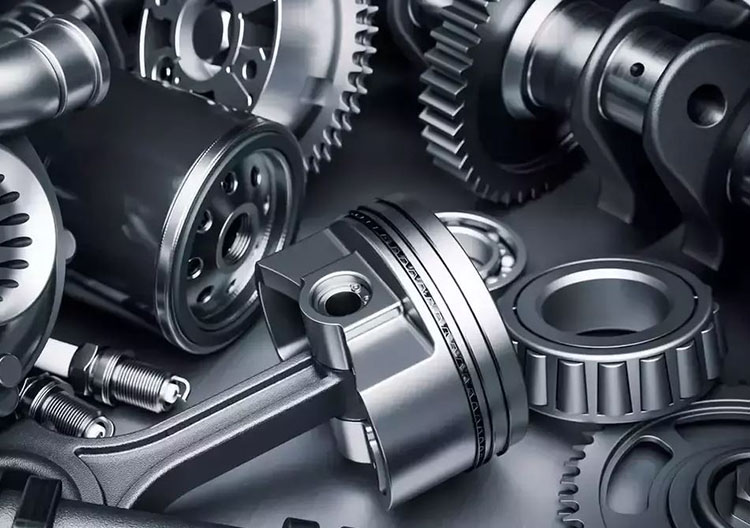

What materials are used to produce vehicle construction castings parts?

Aluminum stands out as the predominant alloy in automobile part construction, prized for its lightweight properties. This characteristic empowers engineers to craft parts that are both durable and lightweight. Meanwhile, zinc, comprising around 28% of the automotive sector, emerges as another favored option. The most common materials used to produce vehicle construction casting parts are metal alloys, with specific choices depending on the desired properties of the final part.

Aluminum alloys: These are lightweight and offer good corrosion resistance, making them ideal for many engine components, structural parts like shock towers, and even some electronic covers.

Magnesium alloys: Even lighter than aluminum, magnesium offers excellent strength-to-weight ratio. However, it’s more susceptible to corrosion and requires special handling. It might be used for specific high-performance parts where weight reduction is crucial.

Zinc alloys: Affordable and offering good dimensional stability, zinc alloys are often used for smaller, non-structural parts like trim pieces or bezels. However, their strength is lower compared to aluminum or magnesium.

Iron-based alloys: Cast iron is still used for some engine blocks and other components that require high strength and durability. However, due to its weight, its use is being optimized in favor of lighter alternatives.

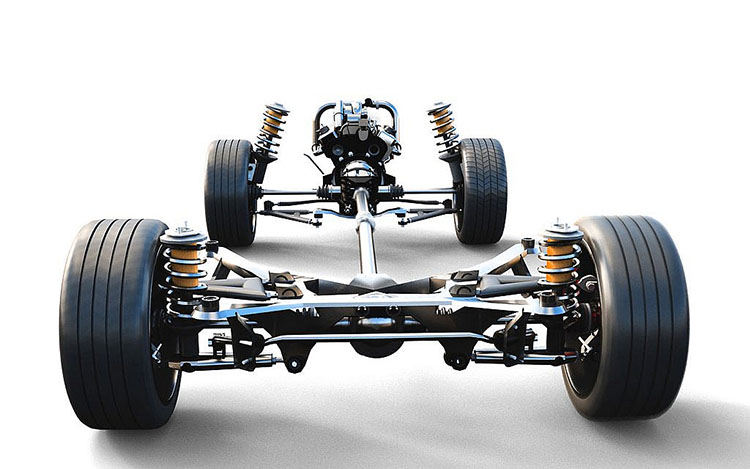

Advantages of using cast parts in construction vehicles

Using cast parts in construction vehicles offers several advantages:

High durability

Construction vehicles often operate in harsh environments and have large loads. Construction vehicle spare parts require high durability. Therefore, parts produced by casting methods, especially parts made from alloy castings, can meet these.

High flexibility in design

Casting methods can create a variety of shapes with complex details. This is suitable for producing parts that are difficult to produce or cost too high by other methods such as machining or welding.

Large volume production

Die casting, a common casting technique, is a highly efficient process suitable for mass production. This allows for cost-effective manufacturing of parts needed in large quantities for construction vehicles.

Light texture

Cast parts made from aluminum or magnesium can be significantly lighter than their steel counterparts. This weight reduction translates to improved fuel efficiency and overall vehicle performance, especially for larger construction equipment.

High precision

Cast parts can be produced with tight tolerances and a smooth surface finish, minimizing the need for additional machining or finishing work. This translates to faster assembly times and potentially lower overall production costs.

What are the costs involved in die casting vehicle construction?

Die casting offers significant advantages over alternative metal manufacturing methods, notably its superior accuracy and repeatability. Moreover, die casting aluminum or zinc proves highly efficient, particularly for vehicle construction component mass production. Several factors influence manufacturing expenses, including material type, wall thickness, part surface area, and tolerance specifications. For detailed cost information, feel free to reach out to GTR Vietnam.

GTR Vietnam – A reputable company providing casting parts for construction vehicles

GTR Vietnam is a renowned company specializing in the manufacturing of casting parts for construction vehicles. With a reputation for excellence and reliability, GTR Vietnam has established itself as a trusted supplier in the industry. The company prides itself on its state-of-the-art facilities, advanced technology, and skilled workforce, ensuring the highest quality standards in every product they deliver. From engine blocks to chassis components, GTR Vietnam offers a comprehensive range of casting solutions tailored to meet the diverse needs of construction vehicle manufacturers. Their commitment to innovation and customer satisfaction makes them a preferred partner for companies seeking reliable casting parts for their construction vehicles.

GTR Vietnam continues to innovate and solidify its position as a leading provider of casting services for construction vehicles in Vietnam and the international market. Trust GTR Vietnam for all your construction vehicle spare parts casting needs, and experience excellence in every aspect of our service.

See more:

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919