Sand casting is a versatile traditional casting foundation for shaping metals in manufacturing industries. Among various casting materials, bronze stands out for its strength, corrosion resistance, and high aesthetic value. For clients and partners seeking high-quality sand casting bronze solutions, GTR Vietnam Casting is a reliable foundry delivering exceptional precision.

What is sand casting bronze?

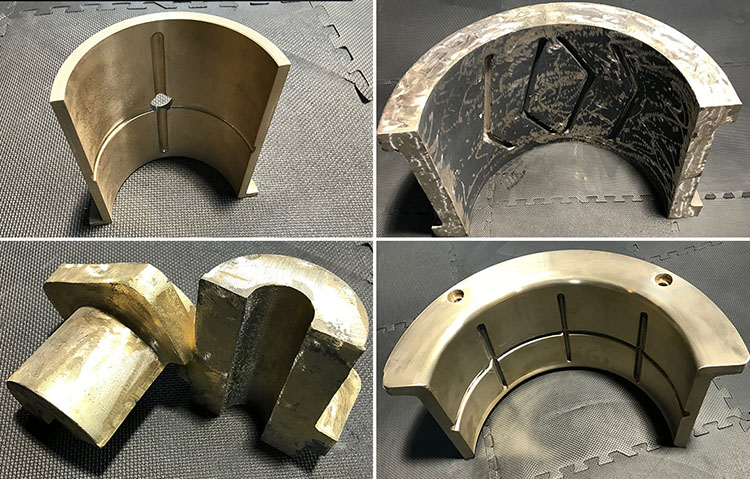

Sand casting bronze is a casting process that uses sand as the mold material for shaping bronze. This method efficiently produces complex shapes while minimizing production costs. The process involves pouring molten bronze into a sand mold and allowing it to solidify before removing the mold to reveal the final product. This flexible casting technique is widely applied across various industries such as construction, machinery, and more.

Why choose bronze for sand casting?

Bronze is a commonly used alloy for sand casting. Its mechanical and chemical properties make it an ideal choice for various applications. Bronze offers excellent corrosion resistance, making it suitable for outdoor and marine environments. Additionally, it has high ductility and exceptional machinability, providing flexibility in manufacturing. Sand casting bronze products are aesthetically appealing, featuring diverse colors and a polished, shiny surface. As a result, sand casting bronze is a popular choice for architectural, sculptural, and decorative products.

Advantages of sand casting bronze

- Cost-effective: Sand casting bronze is a relatively low-cost metal casting method, particularly when producing large quantities from a single pattern.

- Custom design: Sand molds are highly adaptable, enabling the creation of complex designs and precise specifications.

- Scalability: Sand casting bronze is suitable for both small-batch production and large-scale manufacturing.

- Material versatility: Bronze comes in various alloys, each tailored to meet specific application requirements.

GTR Vietnam Casting: Your trusted partner

GTR Vietnam Casting is a trusted company specializing in providing metal casting solutions, including static casting and sand casting for bronze. GTR’s skilled team of experts works closely with clients to ensure that every project meets their expectations. Why choose GTR Vietnam Casting?

- Expertise in casting: GTR excels in offering static casting, investment casting, sand casting, and 3D prototyping solutions.

- Commitment to quality: Stringent quality control processes at every production stage ensure all products meet high standards.

- Modern technology: Advanced equipment and cutting-edge technologies are utilized to deliver high-precision, top-quality products.

Sand casting bronze is a timeless technique that continues to play a vital role in modern manufacturing. For businesses, GTR Vietnam Casting offers reliable and high-quality solutions that combine tradition with technology. Whether you need intricate designs or durable industrial parts, GTR Vietnam Casting is equipped to bring your vision to life. Contact GTR Vietnam Casting today to explore their range of sand casting bronze services and discover how they can enhance your next project.

See more:

- Investment casting for electric vehicles: Enhancing precision and efficiency

- Advances in sand casting technology: Revolutionizing metal casting processes

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919