GTR Vietnam is a leading supplier for precision mechanics casting parts, we specialize in delivering high-quality, custom-engineered parts for various industries worldwide. At GTR Vietnam, we understand the critical role that precision plays in modern engineering and manufacturing. That’s why we employ cutting-edge technology and stringent quality control measures to ensure that each component meets the highest standards of accuracy and reliability.

What are precision mechanics components?

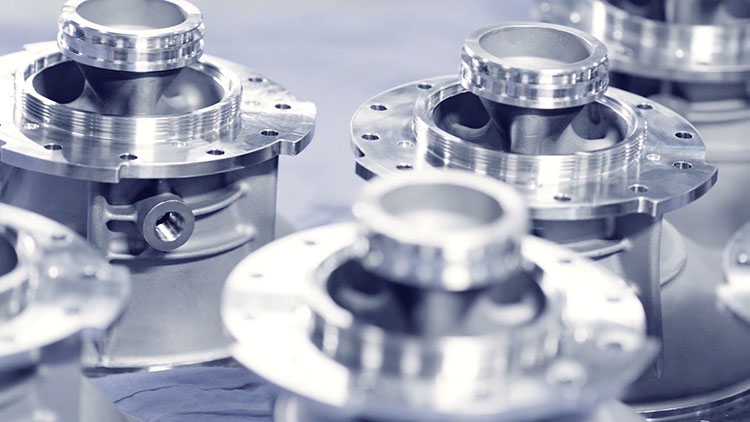

Precision mechanics parts are mechanical components that are manufactured with extremely tight tolerances and high levels of accuracy. These parts are designed and produced to perform specific functions with precision and reliability. They are commonly used in various industries where exact measurements, fine adjustments, and consistent performance are essential. Some examples of precision mechanics parts include bearings, shafts, pistons, gears, valves, nozzles, precision screws,…

Overall, precision mechanics parts are critical elements in the design and manufacturing of machinery and equipment across various industries.

Advantages of using precision mechanical casting parts

Using precision mechanical casting parts offers several advantages:

High accuracy

Precision casting techniques can achieve tight tolerances and fine surface finishes, resulting in parts that meet exact specifications. This high level of accuracy ensures consistency and reliability in the performance of mechanical systems.

Complex geometries

Precision casting allows for the production of intricate and complex shapes that may be difficult or impossible to achieve using traditional machining methods. This enables designers to create innovative and optimized designs for mechanical components.

Cost efficiency

Despite the initial tooling and setup costs, precision casting can be cost-effective for large production runs due to its ability to produce parts with minimal material waste and reduced machining requirements. It can also eliminate the need for multiple assembly steps by producing near-net-shape components.

Material flexibility

Precision casting can be used with a wide range of materials, including various metals and alloys, allowing manufacturers to select the most suitable material for the application. This versatility ensures that mechanical components can meet the required mechanical properties and performance criteria.

Improved mechanical properties

Depending on the casting process and material used, precision cast parts can exhibit superior mechanical properties, such as strength, hardness, and durability. This makes them suitable for demanding applications in industries such as aerospace, automotive, and energy.

Overall, the advantages of using precision mechanical casting parts include the ability to produce complex, accurate, and cost-effective components with a wide range of materials, offering increased design flexibility and improved performance in various applications.

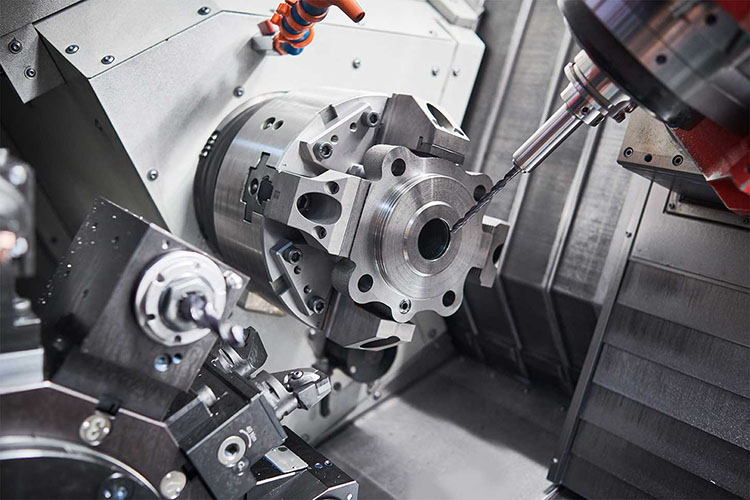

How are precision mechanics casting parts made?

The process of casting precision mechanical components involves several intricate steps to ensure the accurate reproduction of intricate designs and specifications. It begins with the creation of a detailed mold or pattern, typically made from metal, wood, or resin, which serves as a negative of the desired part. This mold is then prepared by coating it with a release agent to facilitate easy removal of the finished component.

Next, molten metal or alloy is poured into the mold cavity under controlled conditions, allowing it to solidify and take the shape of the mold. Once cooled, the casting is removed from the mold and undergoes various finishing processes such as machining, grinding, and polishing to achieve the final dimensions and surface quality.

Quality control measures are implemented throughout the process to ensure that each component meets the required specifications for precision and performance. The casting process is a vital aspect of manufacturing precision mechanical parts, enabling the production of complex geometries and intricate details with high accuracy and repeatability.

Why is GTR Vietnam a reliable casting parts supplier for precision mechanics manufacturers?

Partner with GTR Vietnam today and experience the difference that precision engineering can make in your projects. Contact us to learn more about our services and how we can help you achieve your goals.

GTR Vietnam maintains high quality standards with strict control processes such as ISO 9001:2015 and IATF 1649, using modern technology to ensure product precision and surface quality. Their team of experienced engineers and technicians provide technical support and customized solutions, meeting any specific requirement.

GTR Vietnam offers a wide range of high quality materials, ensuring mechanical performance and durability for various applications. Their commitment to innovation and continuous improvement keeps them ahead of new trends and technologies. They also manage an efficient supply chain for on-time delivery, combined with dedicated customer service and competitive pricing, creating a trusted partner in the precision engineering industry.

See more:

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919