GTR Vietnam specializes in providing top-notch CNC machining services, catering to a diverse range of industries with precision and efficiency. Our state-of-the-art facilities and highly skilled technicians ensure that we deliver exceptional results to meet our clients’ exact specifications. Partnering with GTR Vietnam for your CNC machining needs means gaining a reliable and trusted ally dedicated to exceeding your expectations. Contact us today to learn more about how we can support your manufacturing requirements and propel your business forward.

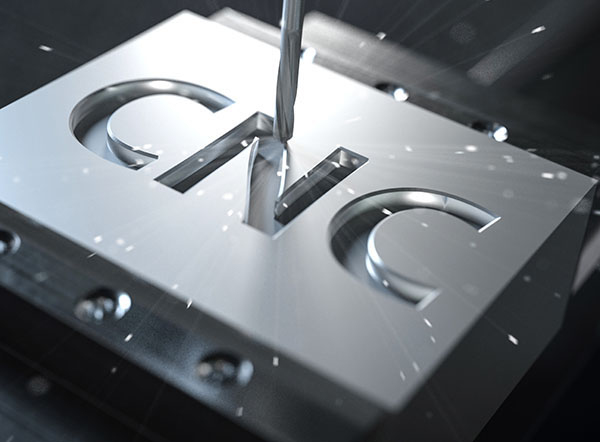

What is CNC machining?

CNC machining is a manufacturing process using machines that apply Computer Numerical Control technology to create products with high precision, optimize working speed, and save labor. During the CNC machining process, the CNC machine will remove materials from a solid block according to the CAD model to create the required details.

This machining method allows designers to adjust the design and material blanks to suit the design format. This avoids processing the product with excess or missing materials while performing work, helping the product to be completed at its best.

Advantages and disadvantages of CNC machining

Advantage

The biggest advantage of CNC machining is that it saves processing time compared to traditional methods. With a pre-designed modern programmed machinery system, the machine will automatically process accurately in the fastest time.

Besides, this machining will reduce labor costs. With CNC machining, products are mass produced more easily and quickly than ever before, producing consistent output. In particular, CNC has high serializability, allowing software to be quickly programmed to create completely new products and correct existing errors.

Disadvantages

Besides the advantages, this machining also has some disadvantages such as:

Investment costs for CNC machinery systems are quite high, many businesses do not have enough funds to equip technology. Besides, this machining depends on computers and software, so if errors occur, it will disrupt the operation process.

Although this machining can machine a wide variety of materials and shapes, there are still limitations in the size of the parts and some materials with too high hardness cannot be CNC machined.

To limit the above problems, customers can choose CNC machining services from reputable companies. CNC machining units have modern technology systems and highly specialized staff to minimize risks in the production process.

Popular materials used in CNC processing

Aluminum Alloys: Aluminum 6061, Aluminum 5052,…

Copper Alloys: Copper 101, Copper C110, Copper C932,…

Brass Alloys: Copper 260, Copper 360,…

Stainless Alloys: Nitronic 60, Stainless Steel 15-5,…

Steel Alloys: Steel 1215, Steel 1018,…

Titanium Alloys: Titanium (grade 2), Titanium (grade 5),…

Zinc Alloys: Zinc Alloy,…

Customize: GTR Vietnam can find other sources of materials and alloys to meet customer requirements.

CNC machining applications

CNC machining plays an important role in the mechanical field, helping to create many high-precision details and parts. Some applications of this machining include:

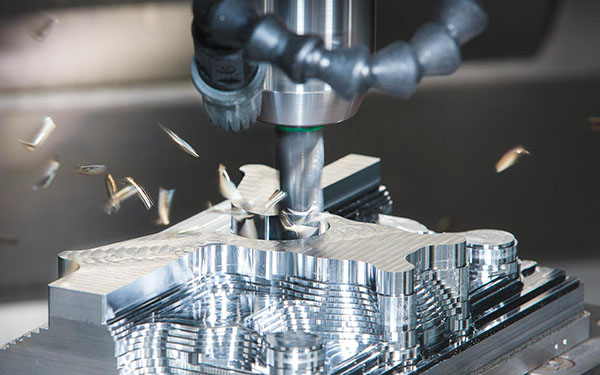

Mold Manufacturing

Creating molds requires high precision, so CNC machining is the right choice. Applying CNC machining to make molds will achieve higher production efficiency and quantity.

High precision components

CNC machining has very strict tolerances, which is very important for details and parts that require high precision and consistency such as bearings, gears, shafts,… on cars and machines. fly. The high repeatability of this machining ensures that every part produced is identical, facilitating easier assembly and integration.

Surface finishing

In mechanical processing, surface treatment of parts is often done manually. This can cause the surfaces and shapes of complex parts to be uneven. However, CNC machining can be easily processed, finished with a smooth surface and high precision.

Quality control and inspection

CNC machines can measure and determine part dimensions during machining, ensuring product quality control. Automated CNC processes help minimize human errors, bringing the best quality to samples and products.

GTR Vietnam’ CNC machining service served for

Automotive industry: Essential components of automobiles such as engines, chassis, transmissions, and other parts.

Vehicle construction: Components, chassis, vehicle parts, Products with intricate details that other casting methods cannot achieve.

Medical: Plastic, equipment, and machinery as conduits, breathing tubes, masks, medical devices, containers, machine casings.

Precision mechanics: Interior decoration, kitchenware, household items, machine components, automotive equipment, aircraft parts, satellites, and medical devices.

Aerospace: Services applications requiring high strength, such as aircraft engines, turbine blades, fuel system components, airframes, and compressor cases.

Why is GTR Vietnam a reliable CNC machining supplier?

Quality management system: The production process at GTR Vietnam complies with international quality standards ISO 9001:2015 and IATF 1649.

Advanced technology: GTR Vietnam has an advanced machinery system and modern, accurate casting technology.

Competitive costs: Competitive pricing ensures affordability and attracts customers looking for value for their money.

Completely solutions: We are specialists in cast components and have many years of strong know-how in the fields of procurement, assembly and logistics

On schedule: We are committed to implementing on schedule and delivering according to customer requirements.

Professional staff: Professional staff and mechanics, rich in experience in the field of casting.

Product variety: GTR Vietnam offers a diverse selection of materials and sizes for your automotive casting needs. This extensive variety ensures you find the perfect fit for your project.

Experience and expertise: GTR Vietnam likely has extensive experience and expertise in the field of casting parts manufacturing for the automotive industry. This experience enables them to understand the specific requirements and standards of automotive manufacturers.

Do you have questions?

How does it work?

This is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece to create a desired shape or product. This machining process is performed in 4 stages:

Stage 1: Creating the CAD model

Stage 2: Converting CAD model to CNC file

Stage 3: Configuring the CNC machine

Stage 4: Machining operation execution

Which industries benefit from GTR Vietnam’s services?

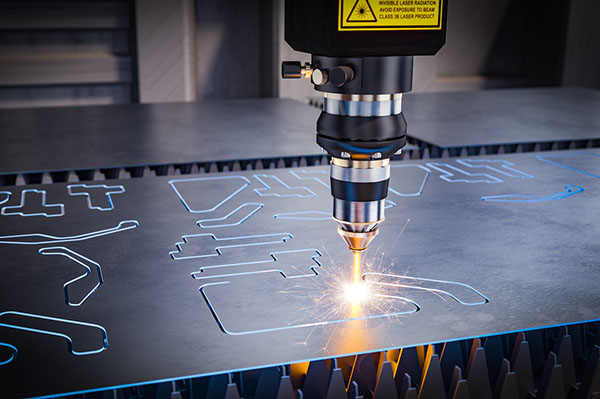

Some other CNC machining processes include:

- CNC Milling

- CNC Drilling

- CNC Grinding

- CNC Routing

What do customers receive when CNC machining at GTR Vietnam?

When customers choose services at GTR Vietnam, they receive a comprehensive package tailored to meet their specific needs and requirements.

- GTR Vietnam employs state-of-the-art CNC machines operated by highly skilled technicians to ensure precise and accurate machining of parts.

- We work closely with our customers to understand their unique specifications and project goals.

- Our facilities are equipped with the latest CNC machining technology, allowing us to offer a wide range of machining capabilities.

- We have rigorous quality control processes in place to ensure that every part meets the highest standards of excellence.

How do GTR Vietnam manage quality assurance?

GTR Vietnam manages quality assurance by adhering to international standards, including ISO 9001:2015 and IATF – 16949 certifications.

See more:

- Professional steel casting – Solutions for all applications

- GTR Vietnam: Professional sand casting for all needs

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919