Utilizing 3D printing-prototyping techniques significantly speeds up the product development process by providing rapid and flexible prototyping capabilities. State-of-the-art machinery ensures precision and efficiency, enabling the production of high-quality prototypes quickly and accurately. GTR Vietnam boasts a team of highly skilled engineers and technicians with extensive experience, who work closely with clients to tailor solutions to their specific needs. GTR Vietnam offers comprehensive services and emphasizes quality assurance, ensuring that every project meets the highest standards of excellence.

What is 3D Printing-Prototyping?

3D printing is a method of adding materials based on the 3D design of the product. This method creates three-dimensional objects by layering material on top of each other in cross-sectional layers of the digital model. Unlike traditional machining methods, 3D models will be created from removing materials from an initial block of raw materials. Products from 3D printing technology have a variety of shapes from simple to complex.

Types of 3D printing technology

FDM printing technology

- Operating principle: Using thermoplastic fibers to melt and squeeze through a nozzle to create details and material layers.

- Materials: PLA, ABS, PETG, TPU and other thermoplastics.

- Advantages: Easy to use, low cost, suitable for beginners, diverse plastic materials.

- Disadvantages: Limited precision and surface smoothness, needs post-printing support.

SLA printing technology

- Operating principle: The method uses a laser beam to shine on a bath of liquid photopolymer resin, causing the resin at the lighting position to solidify, forming layers of material.

- Materials: Specialized liquid plastic (photopolymer)

- Advantages: High precision, good surface smoothness, suitable for printing complex details.

- Disadvantages: High cost, limited printing materials, requires post-printing processing.

SLS printing technology

- Operating principle: Using a projector to illuminate the entire surface of the photopolymer plastic tank at the same time, instead of a laser beam illuminating each point.

- Materials: SLS 3D printing method uses lasers to bond each layer of material powder into the desired shape.

- Advantages: Can print metal materials, high precision, sturdy product, little need for post-printing support.

- Disadvantages: High cost, requires specialized printer, fine dust during printing.

Advantages of 3D Printing-Prototyping

Custom design and creation of diverse products

Applying 3D printing technology can create products with complex shapes and details that traditional manufacturing methods cannot make. In addition, 3D printing technology allows creating personalized products to meet customers’ specific requirements.

Increase production speed

Creating 3D printed prototypes can shorten production time, to just a few days or even a few hours. This method is suitable for sample products and small quantities.

Cost savings

Compared to traditional prototyping methods, 3D printing technology does not require many machines or workers to create products.

Minimize material waste

This is an additive manufacturing method, so only the necessary amount of material is needed, minimizing waste of production materials. 3D printing technology involves creating products from scratch without carving solid blocks like CNC machining.

Application of 3D printing technology

The purpose of 3D printing technology is to create rapid, high-precision industrial prototypes to help speed up the product development stage. Therefore, 3D printing and rapid prototyping are widely applied in the following industries:

Automotive industry: Essential components of automobiles such as engines, chassis, transmissions, and other parts

Vehicle construction: Components, chassis, vehicle parts, Products with intricate details that other casting methods cannot achieve

Medical: Plastic, equipment, and machinery: conduits, breathing tubes, masks, medical devices, containers, machine casings

Precision mechanics: Interior decoration, kitchenware, household items, machine components, automotive equipment, aircraft parts, satellites, and medical devices

Aerospace: Engineering & 3D printing-prototyping services applications requiring high strength, such as aircraft engines, turbine blades, fuel system components, airframes, and compressor cases.

Why is GTR Vietnam a reliable casting supplier?

Quality management system: The production process at GTR Vietnam complies with international quality standards ISO 9001:2015 and IATF 1649.

Advanced technology: GTR Vietnam has an advanced machinery system and modern, accurate casting technology.

Competitive costs: Competitive pricing ensures affordability and attracts customers looking for value for their money.

Completely solutions: We are specialists in cast components and have many years of strong know-how in the fields of procurement, assembly and logistics

On schedule: We are committed to implementing on schedule and delivering according to customer requirements.

Professional staff: Professional staff and mechanics, rich in experience in the field of casting.

Product variety: GTR Vietnam offers a diverse selection of materials and sizes for your automotive casting needs. This extensive variety ensures you find the perfect fit for your project.

Experience and expertise: GTR Vietnam likely has extensive experience and expertise in the field of casting parts manufacturing for the automotive industry. This experience enables them to understand the specific requirements and standards of automotive manufacturers.

Do you have questions?

How is steps to create prototyping using 3D printing technology at GTR Vietnam?

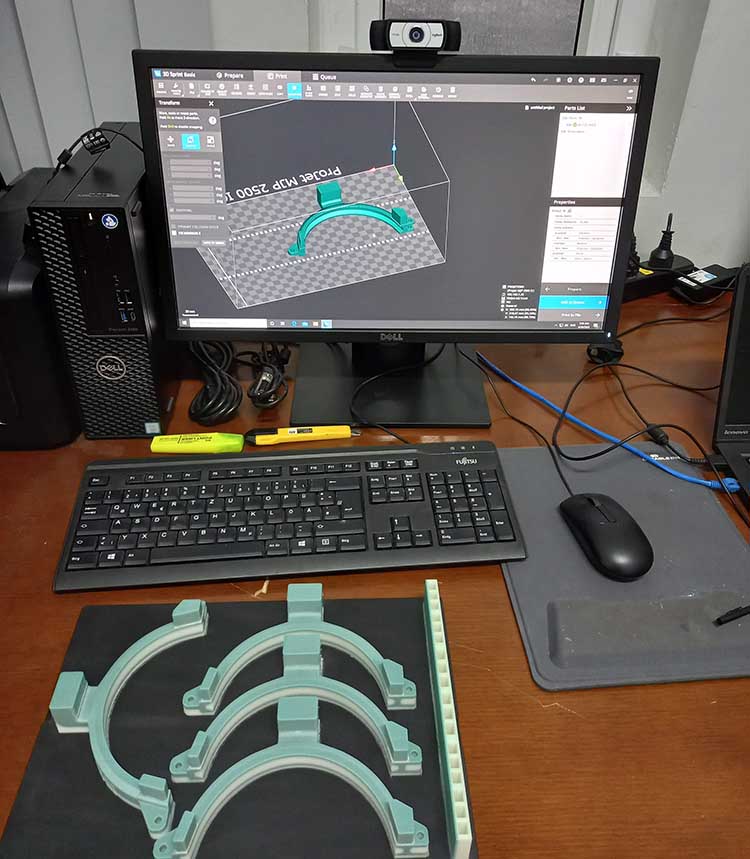

Step 1: CAD design the first step in creating a prototype using 3D printing technology is to design the object in Computer-Aided Design (CAD) software. CAD allows designers to create detailed digital models of the desired prototype, specifying dimensions, features, and other characteristics.

Step 2: Material Selection After the design is completed, the next step is to choose the appropriate material for 3D printing. The choice of material depends on factors such as the desired properties of the prototype.

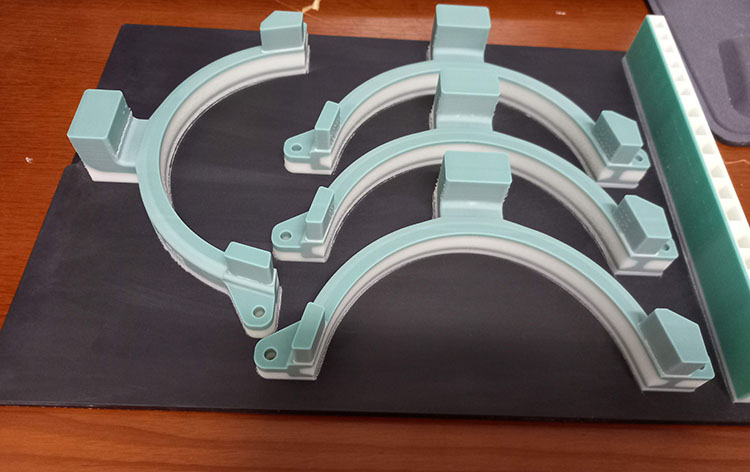

Step 3: 3D Printing During the printing process, the 3D printer builds the object layer by layer based on the digital model created in the CAD software.

Step 4: Optimal Measurement After the prototype is printed, it undergoes optimal measurement to ensure that it meets the desired specifications and dimensions. Engineering using precision measuring tools and techniques to verify the accuracy and quality of the prototype.

3D printing-prototyping is a necessary factor to help implement ideas to consumers more conveniently.

What is the best material for prototyping?

The best material for prototyping depends on factors such as project requirements, required accuracy, and the intended use of the prototype. Some common materials for prototyping include:

- ABS plastic: ABS (Acrylonitrile Butadiene Styrene) is one of the most common materials for prototyping due to its flexibility, durability, and high-temperature resistance.

- PLA plastic: PLA (Polylactic Acid) is a biodegradable and easily recyclable material, suitable for testing models and artistic models.

- PETG plastic: PETG (Polyethylene Terephthalate Glycol) combines the flexibility of ABS and the transparency of PLA, making it suitable for aesthetically demanding applications.

- Nylon plastic: Nylon is a strong, flexible, and high-temperature-resistant material, suitable for applications requiring high durability.

- Resin (UV-curable): Resin is used in UV-based 3D printing technology, creating prototypes with high accuracy and detail.

- Lightweight metals (such as aluminum or titanium) or composites: For applications requiring high strength or extreme accuracy.

What types of projects can GTR support?

GTR can support a range of projects from small to large, including creating prototype models to mass production.

Are GTR’s services customizable?

GTR can customize services according to specific customer requirements, including custom design, 3D printing materials, and other requests.

See more:

- What is die casting? Advantages, types, how it does

- Expert CNC machining for complex components and prototypes

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919