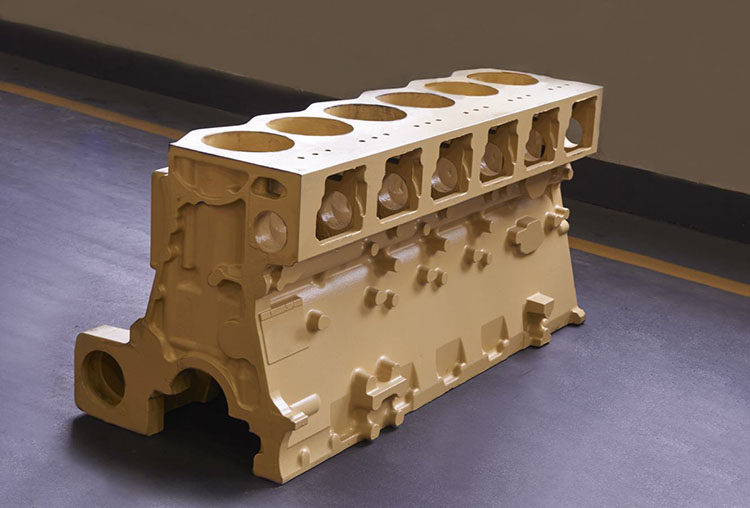

Sand casting, a time-honored casting method, continues to be used and innovated upon in foundries to create a more precise and efficient production process. These advancements have expanded the applications of sand castings in industries such as automotive, medical, energy, and industrial machinery. At the forefront of this development is GTR Vietnam Casting, a provider of static casting, investment casting, and sand casting. Explore the evolution of sand casting in the article below.

Key advances in sand casting technology

Advances in sand casting will result in more precise, high quality, efficient and environmentally friendly products. Some advances in sand casting technology:

Using new materials and alloys

One of the most notable advancements in sand casting is the application of new materials and alloys. High-performance materials with improved heat resistance and corrosion resistance have been developed to make the casting process more efficient. Changes in casting materials have opened up opportunities for applications in industries such as automotive, aerospace, energy, healthcare, and more.

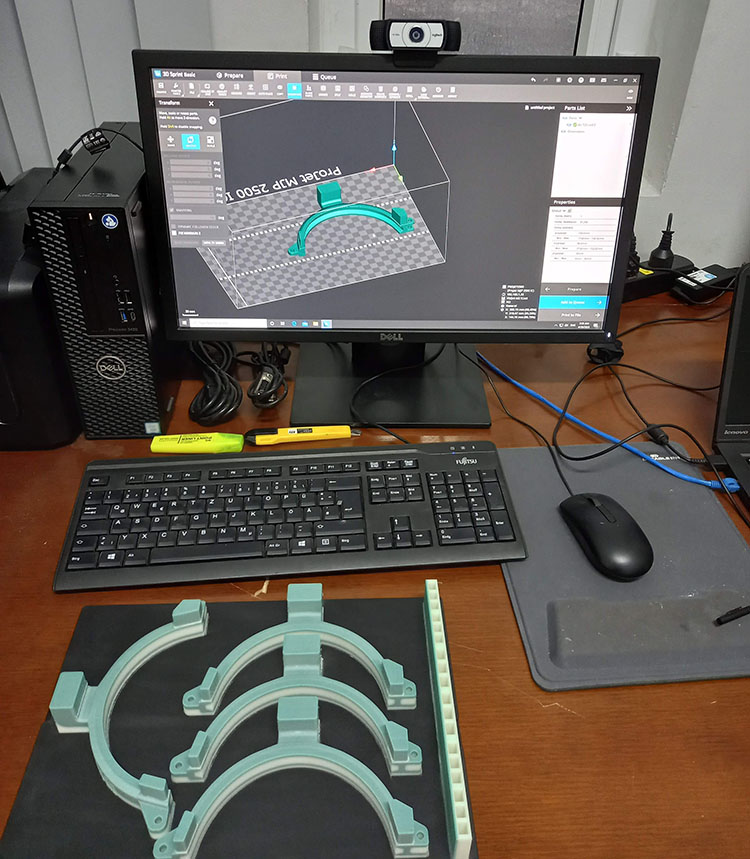

3D Printing of sand molds and cores

3D printing has been widely adopted in the field of metal casting. Compared to traditional manual methods of mold and core production, 3D printing enables the direct printing of molds and cores based on digital designs. This technology offers flexibility in design, faster turnaround times, and cost savings compared to conventional mold-making techniques.

Automated casting technology

Automation and robotics in sand casting enhance efficiency and reduce manual labor. Automated systems perform tasks such as mold assembly, pouring molten metal, and mold removal once the product is complete. The remarkable advantages of automation include minimizing risks and injuries associated with manually handling heavy molds and cast products.

High-quality binders

High-quality bonding agents for sand casting will enhance the strength, dimensional stability, and collapsibility of sand molds and cores. Consequently, this improvement leads to higher dimensional accuracy of castings and reduces defects such as sand inclusions and sand expansion.

Modern simulation software

Modern simulation software has revolutionized the sand casting process. These digital tools enable engineers to optimize mold design, metal flow, cooling rate, solidification modeling, and more. This technology allows for the identification of potential defects prior to production, reducing waste and improving the quality of cast products.

Sustainability initiatives

Environmental considerations have spurred innovations in sand casting. Recyclable sand materials and eco-friendly binders reduce waste and emissions, aligning the process with global sustainability goals. GTR Vietnam Casting is committed to adopting green practices to ensure responsible manufacturing.

Why choose GTR Vietnam Casting?

GTR Vietnam Casting is a leading company in the metal casting industry. We leverage advanced technologies to deliver high-quality casting solutions tailored to customer requirements. With a focus on growth and customer satisfaction, GTR Vietnam Casting ensures reliability and quality in every project.

See more:

- Investment casting for electric vehicles: Enhancing precision and efficiency

- Exploring the future of investment casting: Innovations and trends

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919