Investment casting is one of the oldest metallurgical processes. With a history spanning millennia, this method has continuously evolved to meet the demands of society. This article delves into the historical development of investment casting. Let’s explore!

The origins of investment casting

This metallurgical method dates back approximately 5,000 years. Investment casting originated in ancient civilizations such as Egypt, Greece, Mesopotamia, and China.

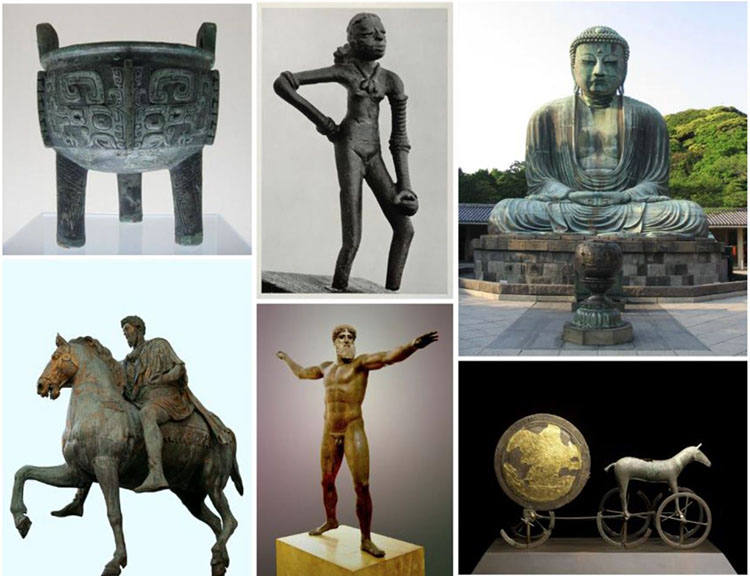

Initially, around 3700 BC, investment casting was used to create statues and jewelry. Beeswax was the material of choice for the pattern, and molds were made from clay. In Egypt, artisans employed this method to produce intricate metal objects for their temples and tombs. The Greeks utilized investment casting to create renowned bronze sculptures. Sculptors in Mesopotamia, ancient Egypt, artisans in China, Aztec goldsmiths in Mexico and Benin craftsmen in Nigeria have also used this method to create masterpieces of art in gold, bronze and copper.

Investment casting in modern times

In the 20th century, the outbreak of World War II increased the demand for the production of metal parts by investment casting to meet the military needs of countries. Investment casting can create precision, complex, high-strength parts that no other metallurgical method can do.

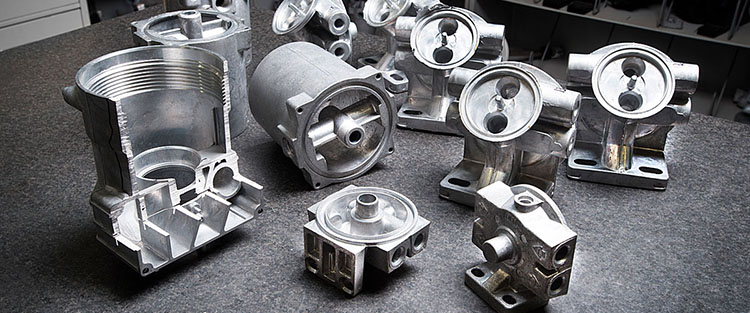

In the post-war period, investment casting has expanded its application to other industries and trade when it is necessary to produce complex metal parts, perfect surface, high strength while reducing processing time and cost.

With the development of materials and manufacturing techniques such as 3D printing, CAD/CAM has promoted investment casting to open a new era. Currently, investment casting is widely used in the aerospace industry to create fan blades, turbines, or parts with complex shapes, requiring light weight and high durability. This method is also widely used in the automotive, medical, and industrial machinery industries.

The future of the casting industry in Vietnam

In Vietnam, the casting industry has gone through many ups and downs. In recent years, the casting industry has developed strongly, with the application of new technology, rapidly increasing foreign investment, and higher production demand. According to the Vietnam Foundry and Metallurgy Science and Technology Association, this industry is currently growing at an average rate of 8-10%/year with a total output of about 1.5 million tons in 2023. Common investment casting application fields are the automotive industry, medical industry, industrial machinery, etc., creating great opportunities for local casting units.

The application of modern techniques such as die casting, investment casting, and cat casting has improved production efficiency and quality. In particular, domestic casting companies also apply technical tools such as simulation software and 3D printing, static support machines to minimize errors and optimize production processes. With investment in infrastructure and updating new technologies, the Vietnamese casting industry is expected to achieve high growth, meeting the needs of many domestic and foreign industries and fields.

However, the metal casting industry in Vietnam still faces challenges such as waste treatment to the environment, the need for high sustainability standards. To solve the above problems, casting companies in Vietnam need to switch to environmentally friendly activities such as using recyclable materials and energy-saving technology.

GTR Vietnam Casting belongs to the parent company GTR Germany, specializing in providing investment casting, static casting, and leading sand casting services in Vietnam. The company produces high-precision, high-durability components and parts for many industries and fields such as automobiles, medical, industrial machinery, etc. Our partners are large corporations worldwide such as Bosch, AMG Mercedes, Jungheinrich, Rolls-Royce (aerospace). If you have a casting project that needs cooperation, please contact us immediately. GTR Vietnam Casting will support and turn your ideas into reality.

See more:

- Exploring the future of investment casting: Innovations and trends

- Investment casting applications: Exploring versatile uses across industries

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919