Investment casting is one of the oldest manufacturing methods, dating back over 5,000 years. Today, this method is widely applied to produce high-quality, durable industrial components. At GTR Vietnam Cast, we specialize in investment casting to manufacture machine parts and components for industries such as automotive, medical, precision engineering, aerospace, and more. Join GTR Vietnam as we explore the various applications of investment casting in the article below.

Investment casting applications

Investment casting is a highly precise method capable of producing complex shapes, making it suitable for various industries. Specifically, investment cast products are applied in sectors such as:

Aerospace industries

In the aerospace industry, there is always a high demand for precision, durability, and lightweight materials. These factors play a critical role in the operation and safety of aircraft. This is why investment casting has become a preferred manufacturing method for components such as jet engine parts and other aerospace applications.

Compared to other methods, investment casting is one of the most optimal production techniques. It minimizes material waste while delivering high-quality aerospace castings. The ability of this process to produce complex components with tight structures and excellent surface finishes, without requiring additional machining steps, makes it the top choice for aerospace applications.

Some common applications of investment casting in aircraft components include turbine blades, compressor housings, fuel system parts, landing gear components, and airframe structures.

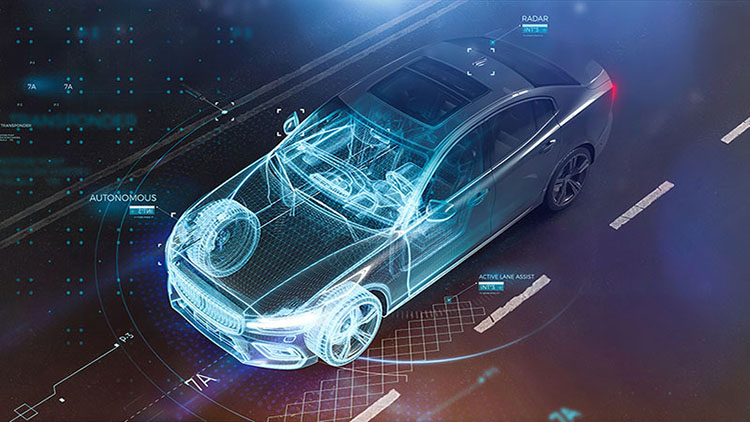

Automotive industries

Investment casting has produced critical components and engine parts for the automotive industry. This method creates complex metal parts by pouring molten metal into wax molds. The resulting products exhibit high dimensional accuracy, superior surface finish, and uniformity, making them ideal for automotive applications.

Additionally, the use of investment casting in the automotive industry significantly reduces costs. This process minimizes waste, excess material, and machining time, leading to considerable savings in production costs. Furthermore, investment casting enables the production of lightweight components, which enhance fuel efficiency in vehicles.

Medical industries

The advantages of the investment casting method lie in its high precision and flexibility. This process is ideal for producing complex medical devices and implants that demand exceptional accuracy and a flawless surface finish.

With extensive expertise in professional investment casting, GTR Vietnam Cast can manufacture components and parts using materials such as stainless steel, titanium, aluminum, and cobalt-chromium alloys. Some of the products the company provides include operating tables, surgical room equipment, MRI machines, X-ray devices, stretchers, wheelchairs, and more.

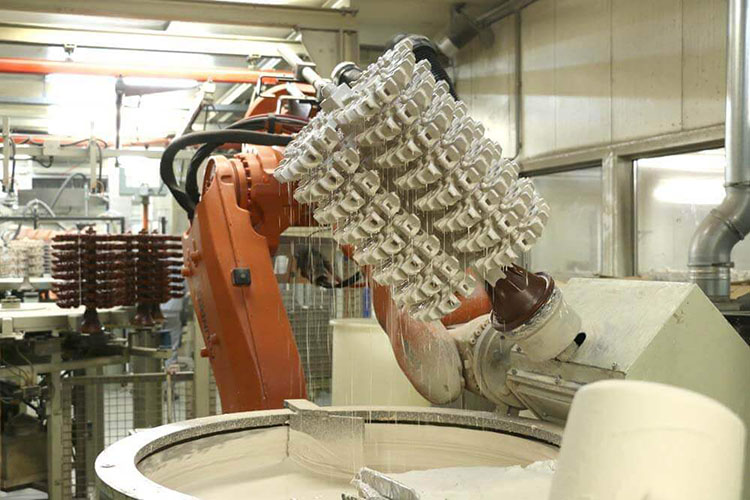

Industrial machinery

Investment casting is widely applied in the industrial machinery sector due to its ability to produce complex components with high durability and precision. This process is capable of manufacturing intricate machine parts such as gears, pumps, and cutting tools.

In addition to these advantages, investment casting minimizes material waste, reduces machining time, and delivers a flawless surface finish. The process also offers flexibility in the choice of casting materials. With these benefits, investment casting has become a preferred method in the industrial machinery industry.

Investment casting is a versatile manufacturing process that finds applications across numerous industries. Its ability to create complex shapes, use a wide range of materials, and meet strict quality standards makes it indispensable for aerospace, automotive, medical, and other sectors.

See more:

- Difference between forging and investment casting

- Popular materials used in investment casting technology

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919