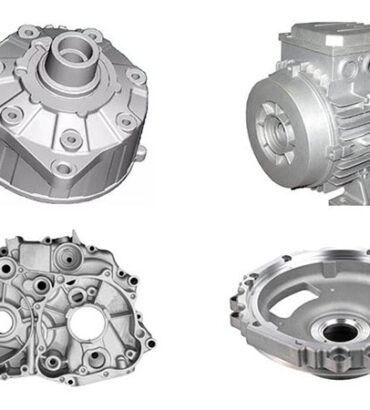

GTR Vietnam engineers automotive casting products designed to maximize performance, durability, and efficiency across diverse applications. Our casting process delivers xceptional strength and optimizes engine power. Meticulously chosen materials ensure our castings have a broad range of potential uses.

Advantages of manufacturing automotive parts casting

Applying casting methods in the production of auto parts brings many benefits to the auto industry. These benefits include:

- Create a variety of shapes: Casting method allows creating parts and components with complex shapes that other processes cannot make. This method is suitable for creating internal car parts with complex design requirements.

- Using a variety of materials: Auto parts can be cast from many different materials such as aluminum, steel, alloy,… to help meet the performance and cost of customers.

- Lower production costs: Auto parts manufactured using casting methods are more cost-effective, especially for high-volume production.

- High strength, seamless construction: Automotive molded parts are very durable and require seamless construction, reducing the need for conformal assembly for critical automotive applications. For example, cast iron is often used for engine blocks and other highly stressed parts due to its excellent mechanical properties.

- Surface finishing: Certain molding processes, such as flow molding, can produce auto parts with excellent surface finishes and high levels of detail, reducing the need for additional finishing activities.

In short, casting is a flexible, cost-effective, and efficient method of producing auto parts, meeting the diverse and rigorous requirements of the auto industry.

What types of products are die-cast specifically for the automotive industry?

Die casting is a popular manufacturing process in the automotive industry due to its ability to produce high-precision, complex parts with excellent surface finishes and mechanical properties. The types of products specifically die-cast for the automotive industry include:

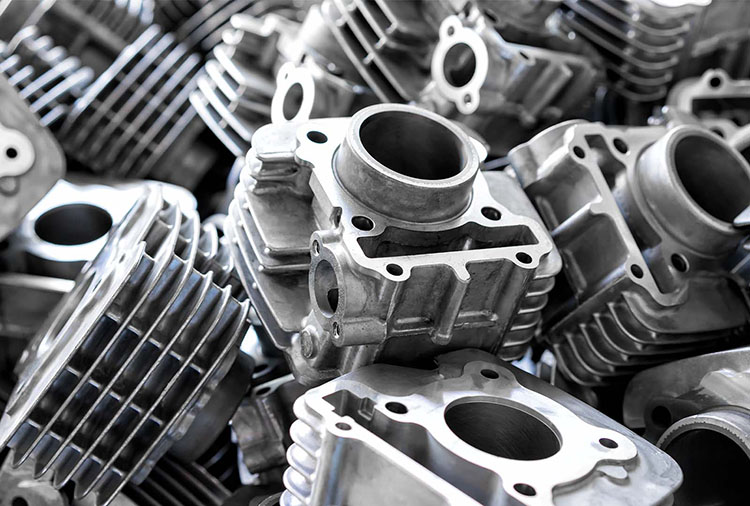

Engine components

Die casting is widely used to create engine components such as cylinder heads, engine blocks, intake manifolds, and valve covers,… Die-cast engine components can be lightweight yet strong, which helps to improve fuel efficiency and performance.

Transmission components

Casting is also used to create transmission components such as housings, gearboxes, torque converter housings and clutch covers. Die-cast transmission components can help to reduce noise and vibration.

Body components

While large body panels are typically stamped from sheet metal, die casting is used for some smaller body components such as door handles, mirror housings, and trim pieces. Casting can produce these parts with a smooth surface finish that requires minimal machining or finishing.

Safety components

Die casting is a good choice for safety components such as airbag housings, and seatbelt components. These parts need to be strong and reliable in order to protect occupants in the event of a crash.

Interior components

Many interior parts, such as instrument bezels, seatbelt components, and HVAC system components are die-cast due to the process ability to produce complex shapes and a good surface finish that can be easily painted or plated.

Why is GTR Vietnam a reliable casting parts supplier for automotive manufacturers?

At GTR Vietnam, automotive casting parts products are manufactured using cutting-edge machinery, ensuring rapid and precise completion. We have established our brand in the international market, becoming a trusted partner for renowned corporations like Mercedes-Benz,…

Quality management system: The production process at GTR Vietnam complies with international quality standards ISO 9001:2015 and IATF 1649.

Advanced technology: GTR Vietnam has an advanced machinery system and modern, accurate casting technology.

Competitive costs: Competitive pricing ensures affordability and attracts customers looking for value for their money.

Completely solutions: We are specialists in cast components and have many years of strong know-how in the fields of procurement, assembly and logistics

On schedule: We are committed to implementing on schedule and delivering according to customer requirements.

Professional staff: Professional staff and mechanics, rich in experience in the field of casting.

Product variety: GTR Vietnam offers a diverse selection of materials and sizes for your automotive casting needs. This extensive variety ensures you find the perfect fit for your project.

Experience and expertise: GTR Vietnam likely has extensive experience and expertise in the field of casting parts manufacturing for the automotive industry. This experience enables them to understand the specific requirements and standards of automotive manufacturers.

See more:

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919