Die casting is a popular casting method, used in the production of complex details and parts in industries. So what is die casting? What are the advantages of this method? Let’s learn about pressure casting with GTR Vietnam through the following article.

What is die casting?

Die casting is the process of casting metal parts and components. The molten metals are then poured into pressure casting molds. The flow in the mold will solidify under the influence of high pressure or low pressure. Pressure casting is the process of casting metal parts and components. The molten metals are then poured into pressure casting molds. The flow in the mold will solidify under the influence of high pressure or low pressure. This molding process is highly efficient, creating precise parts with high requirements for size and surface. Pressure casting is suitable for producing complex parts. This is a superior casting method widely used in industries such as automotive, aerospace, medical, precision engineering,…

GTR Vietnam pressure casting services

GTR Vietnam cooperates with reputable, quality pressure casting manufacturing companies to provide pressure casting parts according to customer requirements for many different industries. Whether you require small-scale production or high-volume production, GTR Vietnam is equipped to handle your project with the utmost professionalism and proficiency. Partner with GTR Vietnam to meet your molding needs and experience the difference precision engineering can make.

GTR Vietnam owns a modern machinery system and a team of professional, experienced technicians to ensure providing customers with high quality, accurate gravity molding products. With the motto “Quality makes a brand”, GTR Vietnam always puts customers’ interests first, bringing absolute satisfaction through each molded product.

Common types of pressure casting

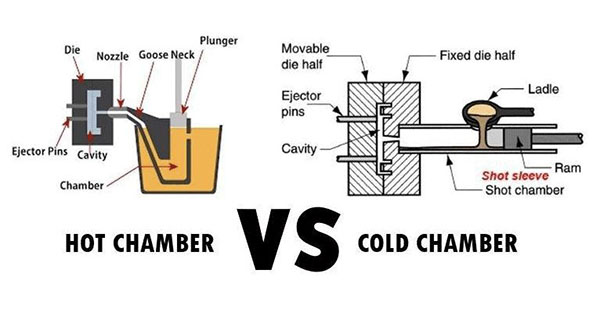

At GTR Vietnam, we provide many types of pressure casting, serving a variety of customer needs. Each type of casting will have its own benefits, suitable for different products and parts. There are two common types of pressure casting: hot chamber die casting and cold chamber die casting.

Hot chamber die casting

Hot chamber die casting is an efficient metal casting method that allows the production of high-quality products at a rapid rate. This casting method is suitable for metals with low melting temperatures such as magnesium, zinc, and lead.

With this method, the metal is melted and poured into the cylinder. The plunger then pushes the metal into the mold through great pressure. The metal in the mold will be cooled and the required finished products will be created.

Cold chamber die casting

Cold chamber die casting is often used for materials with high melting temperatures such as copper, aluminum, etc. The operating process of this casting method is pouring molten metal into a firing chamber installed according to the mold system. and molding machine. The plunger will push the metal from the shot chamber into the mold cavity at high pressure.

What materials are commonly used in pressure casting?

Aluminum alloys: Excel in aluminum pressure casting, leveraging its lightweight, corrosion-resistant properties to produce high-quality.

Zinc alloys: Create intricate, durable parts with excellent surface finish, making them ideal for consumer goods, electronics, and automotive industries.

Magnesium alloys: Magnesium is a metal with high corrosion resistance, lighter weight than steel, providing high durability for various industrial parts, especially in the automotive field.

Advantages of pressure casting

Pressure offers several advantages that make it a popular manufacturing process for producing metal parts with high precision and efficiency.

- Pressure casting allows for the production of parts with tight tolerances and intricate designs. This results in high-quality components with excellent dimensional accuracy.

- The pressure casting process produces parts with a smooth surface finish, reducing or eliminating the need for secondary machining or surface finishing processes.

- Pressure casting is a highly efficient process that allows for the rapid production of large quantities of parts. This makes it ideal for mass production and large-scale manufacturing operations.

- Pressure casting minimizes waste as it uses precise amounts of metal, reducing material costs and improving overall efficiency. The process also allows for the recycling of excess metal.

- While the initial setup cost for pressure casting can be high, the cost per unit decreases significantly with high-volume production, making it a cost-effective option for large-scale manufacturing.

What is the pressure casting process at GTR Vietnam?

Which industries utilize pressure casting? GTR Vietnam’ pressure casting service served for

Automotive industry: Essential components of automobiles such as engines, chassis, transmissions, and other parts

Aerospace: Casting services applications requiring high strength, such as aircraft engines, turbine blades, fuel system components, airframes, and compressor cases.

Vehicle construction: Components, chassis, vehicle parts, products with intricate details that other casting methods cannot achieve

Medical: Plastic, equipment, and machinery such as conduits, breathing tubes, masks, medical devices, containers, machine casings

Precision mechanics: Interior decoration, kitchenware, household items, machine components, automotive equipment, aircraft parts, satellites, and medical devices

Do you have questions?

What makes GTR Vietnam’s die casting stand out?

GTR Vietnam’s die casting is distinguished by its commitment to quality, precision, and innovation. With state-of-the-art technology and a skilled team, we deliver exceptional results that meet the highest industry standards.

How does GTR Vietnam ensure the quality of pressure casting parts?

At GTR Vietnam, quality is paramount. We employ rigorous quality control measures throughout the pressure casting process, from material selection to final inspection. Our commitment to excellence ensures that every part meets or exceeds customer expectations

What sets GTR Vietnam apart in terms of environmental responsibility?

GTR Vietnam is dedicated to sustainability. We prioritize eco-friendly practices and strive to minimize our environmental footprint. Through efficient processes, waste reduction, and recycling initiatives, we contribute to a greener, more sustainable future.

How does GTR Vietnam address common defects in pressure casting?

At GTR Vietnam, we utilize advanced techniques and meticulous attention to detail to minimize defects in pressure casting. From design optimization to process refinement, we proactively identify and resolve issues to deliver flawless results.

What support does GTR Vietnam offer during the pressure casting process?

GTR Vietnam offers comprehensive support throughout the pressure casting process, including design assistance, material selection, prototyping, and post-casting finishing. Our dedicated team is committed to ensuring a seamless experience from start to finish.

Contact GTR Vietnam immediately for free consultation:

Address: Hall X2, Hai Thanh industrial zone Duong Kinh ward Hai Phong, Vietnam

Website: https://gtrvietnamcast.com/

Email: info@gtrvietnamcast.com

Hotline: +84 2253 660919