Versatile in use : Casting application & areas of application

Arguments for the use of cast components:

1. Casting is the shortest way from liquid metal to the finished part

2. Casting offers free design of components with great variety

3. Casting is one of the most economical forming methods

4. Casting offers the possibility of almost all materials, unit weights from 1 gram to more than 1 tonne

At GTR Vietnam, almost all standardized steel alloys are offered in investment casting, as far as an economical production is possible due to the number of pieces. Special materials such as aluminum, cobalt or nickel-based materials are available on request. Areas of application include the automotive industry, vehicle construction, medical technology, general mechanical engineering, the food industry, and the chemical or petrochemical industry. Cast components are environmentally compatible and almost one hundred percent recyclable. They thus form a closed cycle and make a decisive contribution to waste avoidance and resource conservation.

Expertise for best results : Consulting, engineering & 3D printing-prototyping

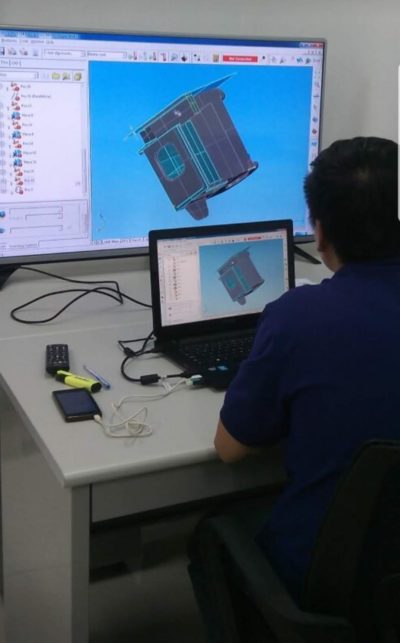

Each of your inquiries or drawings goes through our engineering department and it is checked

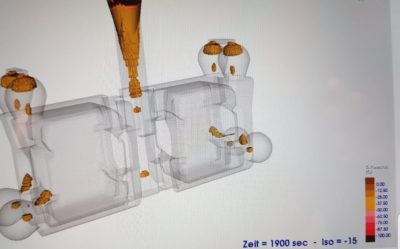

in advance which of our supplier foundries is suitable to manufacture these products. A simulated

solidification and printing of 3D wax models can be performed in advance to ensure optimal

quality. This saves valuable time and costs.

:

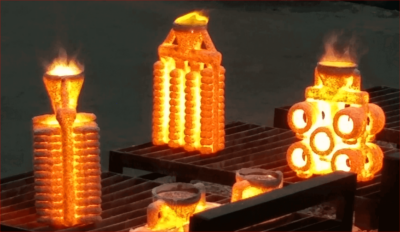

Based on suitable 3D data, prototype production or investment casting prototyping can begin

immediately and the first castings are available after 10 to 14 working days. The combination

of simulated solidification, 3D printing of wax models and the possibility of casting in our own

prototype investment casting shop or directly at our partner companies creates the basis for rapid

prototyping production.